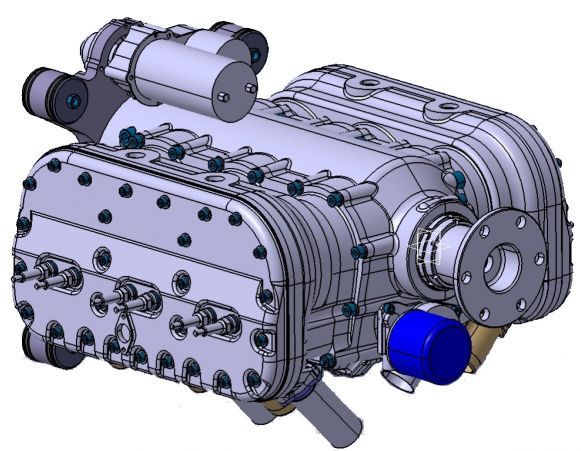

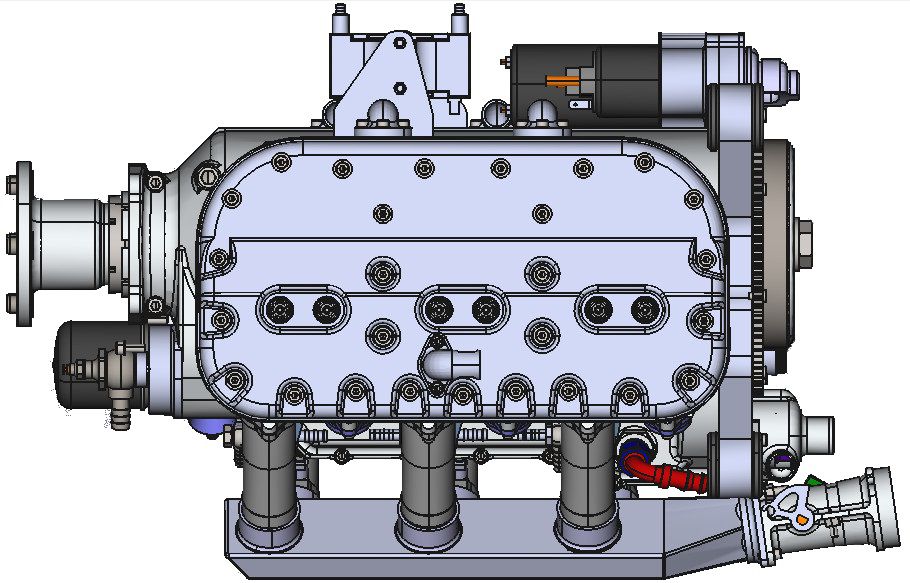

LF39, 6 cylinder 3900 cc liquid cooled engine

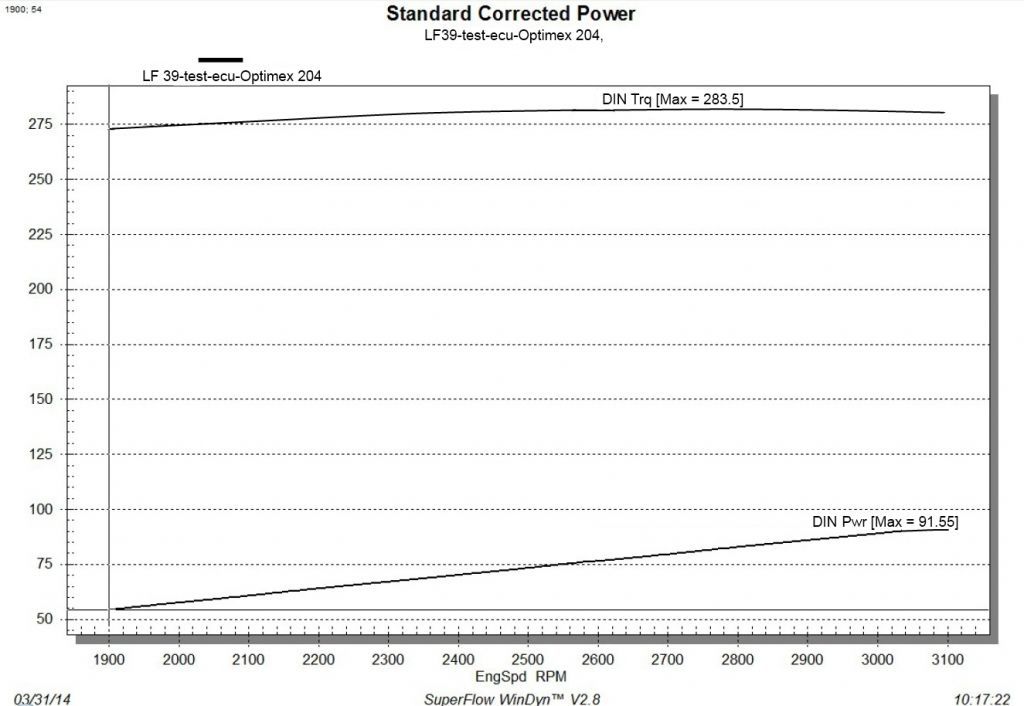

The 6 cylinder serial production started June 2015. Tests on the dyno started in July 2013. First installation was done on a German helicopter from EDM Aerotec in June 2014 (CoAX-2D). In the meantime 30 engines were delivered to helicopter companies. Middle of 2014 the 6 cylinder was also installed on a plane. Because this engine is very similar to the 4 cylinder with a lot of common parts that have already proven to be reliable, we launched this engine in the middle of 2015. The power is 125 with a maximum torque 283 Nm.

COMPACT

By using the flathead engine instead of a overhead engine, we could make the engine smaller despite the big cubic capacity.

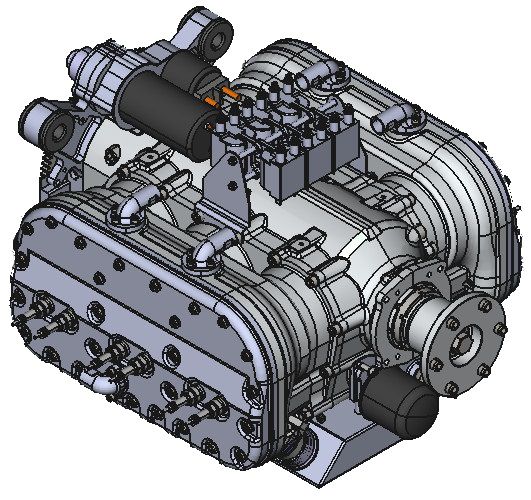

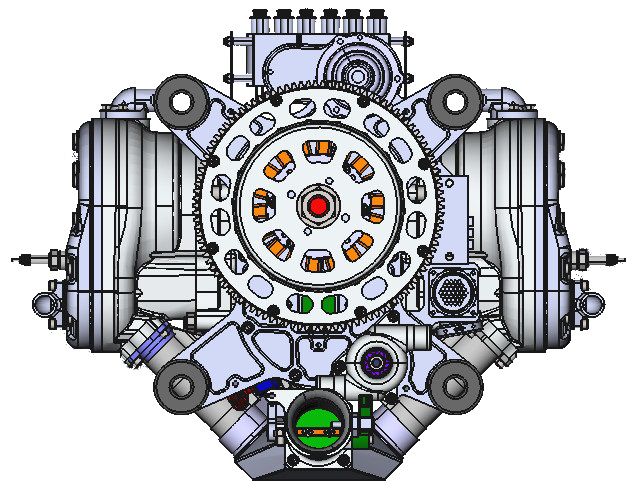

SIMPLE

With the flathead engine, we could make it much simpler and do not have the complexity of the rockers. One of our customers wrote on a blog after exploring the inside of the engine "This engine will go a long way. After fiddling in it's belly, I have even more faith in the mechanics of the engine. It is so simple, there is not much that can go wrong."

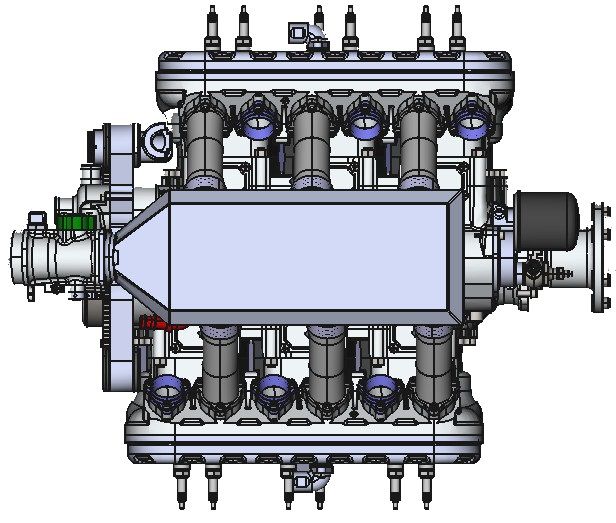

LIGHT

The extra weight of the cooling liquid cooling is compensated by the the flathead design, as we do not have the overhead parts with cooling ribs. The liquid cooling makes it possible to practise "touch and go's" without any danger for thermal shocks or hotspots. It further improves fuel efficiency and lowers emissions.

STRONG

We choose for big cubic capacity resulting in a high torque, and direct driven, because we feel more comfortable with a big engine running lower RPM instead of a smaller engine running high RPM. We took one of the good points of high RPM engines by choosing for nikasil treatment for the cylinders. This treatment is used for motorbike engines and racing engines running up to 12.000RPM. At a red line of 3000 RPM this treatment is an extra guarantee for a long life.

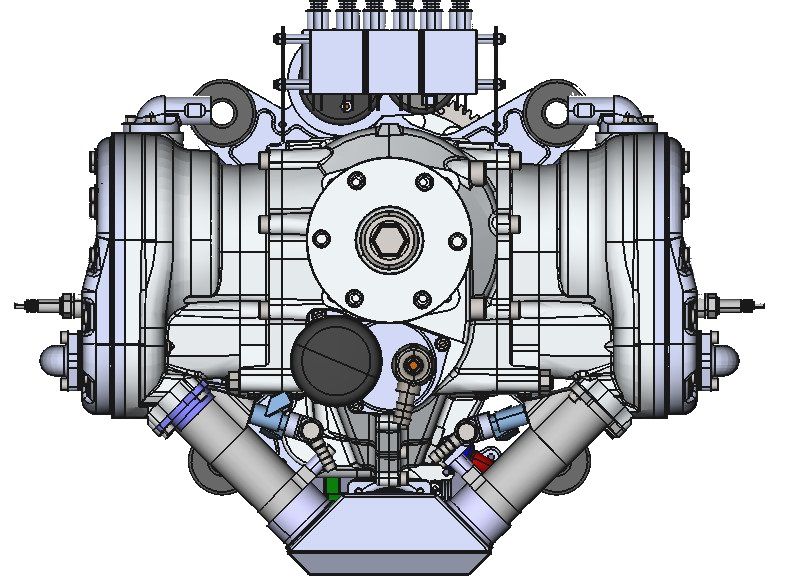

SAFETY

When a valve of an overhead engine is not closing, the engine stops and expensive repair is the result. When a valve of a sidevalve engine is not closing, you continue flying with less power and there won't be expensive repair cost.

European sales

We deliver your engine in a KIT, or install the engine in your airplane/helicopter/drone

The D-Motor engine is unique. The torque is guaranteed nearly flat from 2000 RPM to 3000 RPM. The installation of the engine and the tuning is important. At D-Motor we offer two business models :

* You buy our engine in a KIT (and choose what backplate, add-ons you want us to provide)

* You buy our engine and we install the engine in your airplane/helicopter or drone. Installation will be in our headquarters (near to EBMO and EBKT) or on

site. We quote for the installation, tuning and commissioning.

The 25,50,100, ... maintenance can be done by our technicians, or done by yourself.

All necessary manuals are stored on our DROP system (ask for your login credentials)

Contact us for US, Canadian, african and far east installations.

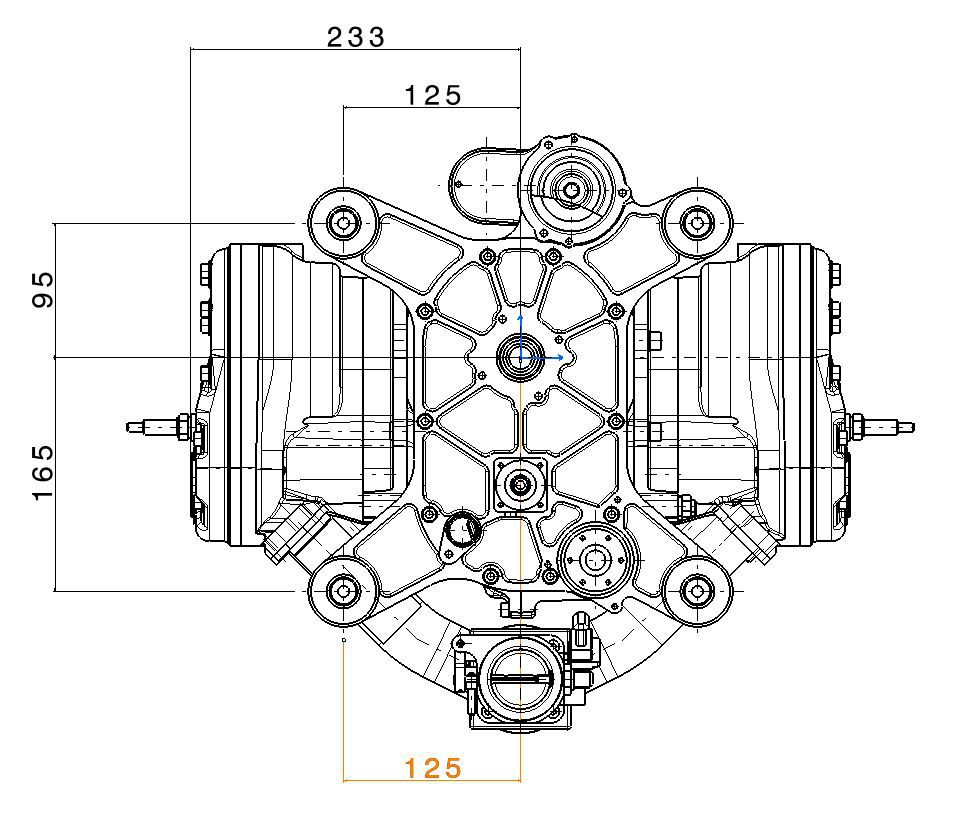

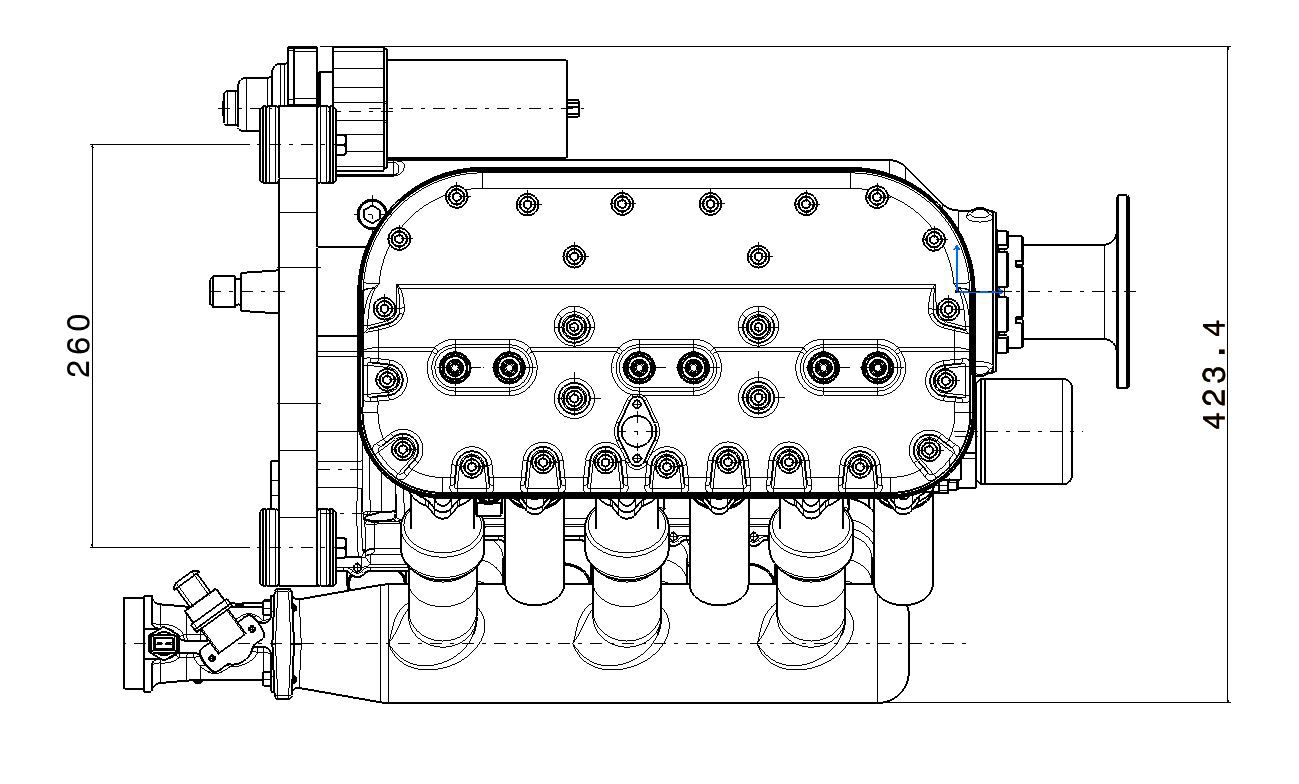

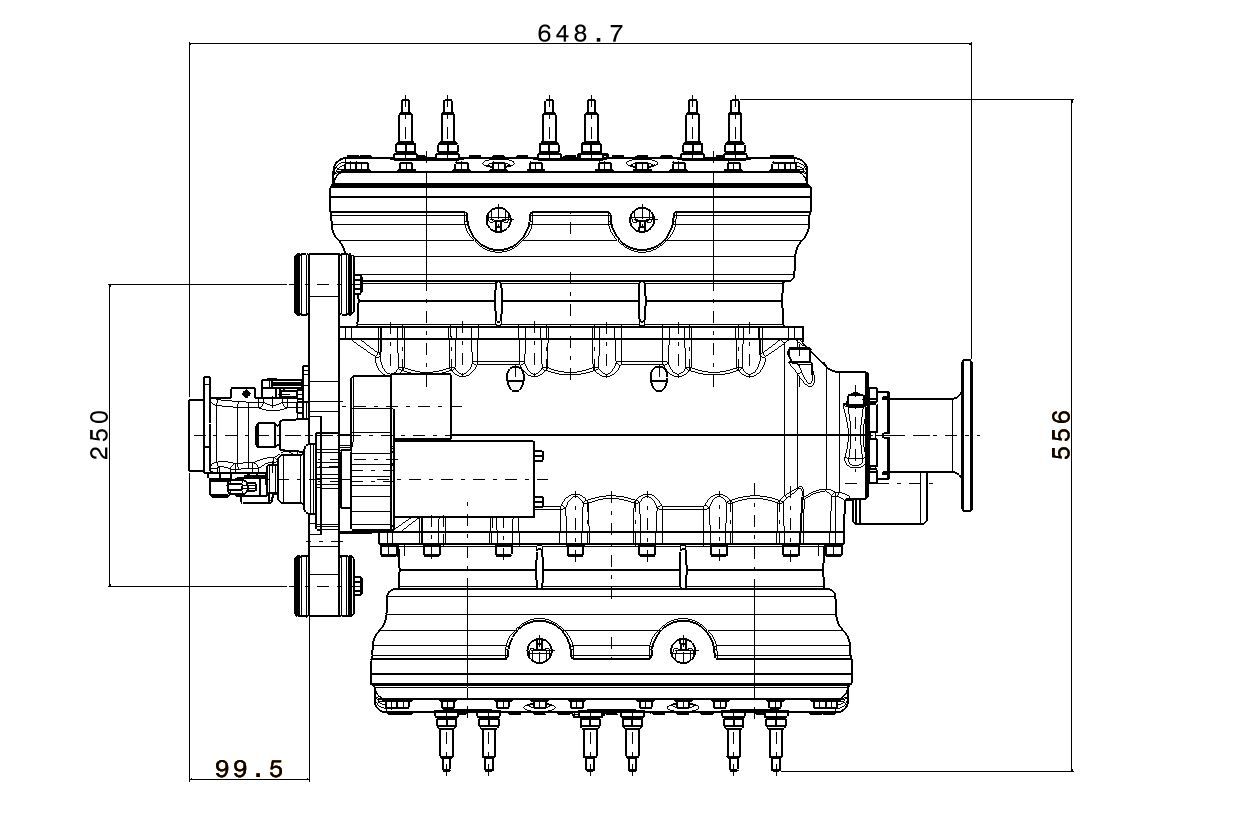

Dimensions

Specifications

-

Type: D- motor LF39

-

Class: Microlight aircrafts

-

Engine: 6 cylinders, four stroke, liquid cooled

-

Displacement: 3993 cc

-

Stroke: 79 mm

-

Compression ratio: 8/1

-

Max power: 125 Hp at 3000 RPM

-

Max continuous power: 112Hp hp at 2800 RPM

-

Used fuel: 91, 93, 95 oct. 98 oct. or avgas

-

Fuel consumption: 19 liter at 75% performance

-

Maximum torque: 285 Nm at 2500 RPM

-

Intake: Multipoint sequential fuel injection

-

Alternator: 25 Amp integrated

-

Electric starter: 1.1 KW integrated

-

Ignition: Double

-

Installed dry weight (liquids 7kg): 78 kg

Included accessories

Delivered with standard engine package:

-

The engine with integrated alternator, water pump, oil pump and electric starter.

-

Rubber mounts (dimensions same as Jabiru and UL power)

-

Fuel pump, fuel filter and injectors

-

2 ignition coils, spark plugs and ignition leads

-

ECU and loom (standard redundant injection)

-

3 water temperature sensors (2 for ECU and one for instrument)

-

Oil pressure and oil temperature sensor

-

Oil radiator, oil filter, oil tank with breather system and hose + connectors

-

Exhaust pipes included and lambda probe.

-

The liquid cooling system (radiator, hoses and expansion tank) are not included.

The different aircraft and helicopters, equipped, required different cooling configurations. It is too difficult to anticipate a solution for every installation. Attempting to provide a universal solution would be both inefficient and overly expensive.

The weight of the engine completely installed with liquids is 85 and 88 kg depending on installation. This weight does not include the engine mount or propeller.

The actual TBO time is 1500 hours.

Options:

-

Plywood crate (FAO-IPPC-ISPM15), packaging and handling

Warranty: 2 year

Power and torque