EngineOperationsManual_LF39_2019_2

Share on Social Networks

Share Link

Use permanent link to share in social mediaShare with a friend

Please login to send this document by email!

Embed in your website

18. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 18 ALL 19 - 3 - 2019

19. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 19 ALL 19 - 3 - 2019 Center Of Mass (CG)

35. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 35 ALL 19 - 3 - 2019 Performance Curve of the LF 39 Engine

13. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 13 ALL 19 - 3 - 2019 LF 39 type ENGINE

43. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 43 ALL 19 - 3 - 2019 Page intentionally left blank

31. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 31 ALL 19 - 3 - 2019 Cooling system Liquid cooled (Max. water temperature 100 Deg. C) Max. continuous power keep water temperature between min. 75 & max. 95 Deg. C. 50% coolant by volume. Recommended coolants are: BP Procool and Shell Glyco Shell Water Pump

17. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 17 ALL 19 - 3 - 2019 WARNING !! DUE TO THE PRECISION OF THE ECU CRANKSHAFT ROTATION MEASUREMENT IT IS POSSIBLE TO HAND START THE LF 39 BY ROTATING THE PROPELLER. ALWAYS ENSURE ALL SWITCHES ARE OFF BEFORE WORKING ON THE LF 39 type ENGINE.

5. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 5 ALL 19 - 3 - 2019 Blank Page ( intentionally)

42. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 42 ALL 19 - 3 - 2019 OVERHAULS Major inspections at TBO is to be performed by the manufacturer or approved service centres only. For this purpose the engine is to be sent with its logbook to the manufacturer or the nearest approved service centre. The recommended time between overhaul (TBO) is at present 1500 hours of operation. An increase of TBO due to field experience will be published in the Service Bulletins of the manufacturer. Major r epairs and major modifications are also only to be performed by the manufacturer or by approved service centres, which are authorized by the manufacturer. In case of prop strikes or sudden stoppage, the engine must be disassembled and the crankshaft must b e checked for cracks. This is considered a major repair and must be performed by the manufacturer or an approved service centre.

34. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 34 ALL 19 - 3 - 2019 If torque wrench is not available. Tighten as far as possible by hand with spark plug tool and then 90° for new spark plug and 30° for used spark plugs. When replacing used spark plugs, two points in particular are to be observed: Firstly, under no circumstances must contamination around plug hole fall into combustion chamber. Secondly, plugs must be tightened to the correct torque. Excessive torque tightening can damage the plug, insufficient torque results in poor sealin g and heat dissipation (*) 1 internal and 1 external in the middle of crankcase

1. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 1 ALL 19 - 3 - 2019 D - MOTOR International © AIRCRAFT ENGINE ENGINE OWNERS MANUAL TYPE LF 39 - 6 Cylinder Engine Publication : LF39_2019_ 2 © D - Motor International bvba, March 2019

29. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 29 ALL 19 - 3 - 2019 by increasing RPM to 1800 RPM and bring throttle back to idle. Engine must run smooth and continuously ! Fuel Supply A safe operation of an engine with fuel injection is only given if the fuel supply is s ecured with sufficient pressure in the system. Carburator icing is impossible; vapour lock appears, due to the high pressure in the system, only under very special conditions. The fuel is sucked out of the fuel tank, trough the pre - filter with the water se parator, toward the fuel pump. After the fuel pump the fuel is pressed through the fine - filter into the common rail system. The injectors gets the required quantity of fuel and the rest is pushed back again into the fuel tank. A pressure regulation valve i n the back flow system keeps the pressure of the entire system constant. The permanent circulation in the system avoids an excessive heating of the fuel in the area of the engine and assure a permanent and autonomous ventilation of the system. Troubles in the fuel supply may lead to less performance, unsteady running, higher consumption, and even to a total failure. As prevention the fuel supply system should be inspected regularly for leakages, damages or abnormal signs of use. It is also very important to ensure that no fuel pipes are bended or porous and that all hose clips are tighten. Further it is important that all electric connections are well fixed.

9. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 9 ALL 19 - 3 - 2019 Contact Information D - Motor International factory representatives are available to answer technical questions and encourages suggestions regarding products, parts, or service. If customers have an inquiry or require technical assistance, they should contact their local D - Motor dealer/distributor or field representative. To contact a factory representative, refer to the contact information below: D - M otor International, bvba Houtekiestraat 11 B - 8540 DEERLIJK BELGIUM Customer service department : +32 (0)56 498149 helpdesk@d - motor.eu https://www.d - motor.eu

27. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 27 ALL 19 - 3 - 2019 NOTE For example: Oil temperature is 90°C to 95°C and cooling liquid has about 80°C. Should the difference of the temperature be higher or lower, the oil, the cooling liquid and the sensors needs to be checked. Oil Supply The oil supply is secured by the oil pump and the dry sump system. Mode of operation: The oil pump sucks trough the heat exchanger and the oil filter oil out of the reservoir and press the oil through the different channels toward the lubrication spots. A spring loaded ball valve regulates the oil pressure. The over pressure coming from the movement of the pistons press the oil back in reservoir. Insufficient oil level may lead to heavy damages on the engine. The oil has basically two functions, the lubrication and the inner cooling of the motor. The control of the oil level is very easy and made by a visual control of the s ight tube of the oil reservoir. Same as for the cooling system, also the oil supply system should be controlled regularly and completely. For a complete and intense control of the oil supply system the upper cowling has to be dismounted. The system should be check visually for leakages, damages or unusual signs of use. Open the oil CAUTION! (1) use only oil specified in this manual (2) don’t use any additives .

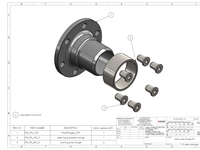

8. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 8 ALL 19 - 3 - 2019 Order of Precedence WARNING The aircraft operator must use the airframe manufacturer’s operating instructions found in the Airplane Flight Manual/ Pilot’s Operating Handbook (AFM/POH) while operating the aircraft unless the AFM/POH directs othe rwise. Updates/Changes Distribution Document updates are available on our web site upon notification of official document approval. Printed publication subscribers receive printed changes and revisions as they are released. Document revisions are releas ed if the update changes more than 50% of the contents of a publication. Revisions replace the previous version of a publication from cover to cover. Minor corrections are released as change pages to the original publication, identified with a change numbe r and effective change date in the page footer. Information on the page that changed from the previous edition is identified by a vertical, six - point black line referred to as a “change bar” in the outside margin of the page. A change page replaces only th e previous edition of the affected page. Suggestions and corrections D - Motor International solicits and encourages user comments regarding suggested changes to this manual. Direct recommended changes or questions to the attention of “Publications” at the address listed in this section, “Contact Information” or send comments via e - mail to info@d - motor.eu . Notify our Customer Service Department immediately, using our telephone number , if you discover incorrect information which adversely affects safety !! Thank you !!

28. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 28 ALL 19 - 3 - 2019 reservoir cap and check if sign of water are visible, especi ally watch out for traces of foam, which is an indication that the oil has some water in it. Verify the hose clips of the oil supply system for tightness and verify that the pipes are not bended. A slightly low oil level does not automatically lead to eng ine damage, but may lead to higher temperature as there is not enough oil available for the inner cooling of the engine. In case the oil temperature increases slowly but continuously it is often an indication of a low oil level. If the oil level is much t oo low in the oil tank, the pipes toward the gear pump may get empty and the gear pump may suck air instead of oil. In such case the required oil pressure is not reached at all or too late. If this happens, stop immediately the engine, refill the oil to ne cessary level and remove the air from the pipe toward the gear pump. NOTE Take care not to waste oil on the ground or inside the engine compartment. Throttle adjustments. Adjust idle speed to 800 RPM using the idle screw on the throttle. Confirm smooth running at idle. Run the engine at 1800 RPM and close the throttle to idle position. The engine should idle smoothly at 800 RPM for fix wings aircrafts. 1010 RPM for helicopters (depending on the choice of the fly wheel). CAUTION! The rotating propeller is extremely dangerous! Adjustments must be done with the utmost caution from behind the engine. The aircraft must be tied down or properly chocked. Do not perform this operations without a safety observer.

26. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 26 ALL 19 - 3 - 2019 The error number 8 may be shown also directly after the start of a cold engine. In this case the required temperature of the probe to make a precise measurement is yet not reached. After warming up the error message should disappear. Safety / Av oiding failures Some failures are announced or get worse over the time. The recognition on time and the analysis of the causes may help to avoid failures of the motor or dangerous situations. Loss of Cooling liquid Loss of cooling liquid leads to an i nsufficient cooling of the engine, respectively too high temperatures and in most cases also to damages or operation malfunctions. For that reason the leak - tightness of the cooling system should be verified regularly. The normal through the maintenance tra p is not sufficient for a complete check of the cooling system. NOTE A damaged sealing surface of the filling cap or a damaged head seal for example, cannot be recognized by controlling the level of the cooling liquid in the overflow reservoir. It is possi ble that when the motor gets warm, the cooling liquid is pressed into the reservoir, but during the engine get colder the liquid is not sucked back in the cooling system of the engine anymore. An indication to that is, for example, if the temperature of th e motor is normal during the flight, but during or after the landing the temperature of the engine does not get down, or even gets higher. For a full check of the cooling system the upper part of the cowling has to be dismounted. All parts and pipes of t he cooling system should then be controlled visually for leakages, damages or signs of abrasion. Verify the hose clips of the pipes for tightness, open the cap of the ventilation tank (only if engine is cold) and verify if the ventilation tank is full of c ooling liquid (level should be just below the sealing surface). Check if the sealing surfaces of the ventilation tank and of the cap are clean and without visible damages. If not please change the damaged parts and refill the cooling liquid if required. Most ULTRA Light aircrafts are equipped with a heat exchanger. In the heat exchanger the oil interact, respectively exchange its heat with the cooling liquid. This means that the cold oil is heated and the hot oil cooled down by the cooling liquid. Once th e engine is heated up to normal range and while it is operated normally (horizontal flight) the temperature of the oil and of the cooling liquid are tightly related to each other, whereat the temperature of the oil should be 10°C to 15°C higher than the co oling liquid.

7. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 7 ALL 19 - 3 - 2019 Warning This is a non - certified aircraft engine ; the possibility of engine failure exists at all times. Do not operate this engine over densely populated areas. Do not operate this engine over terrain where a safe, power off landing cannot be performed. The operating and maintenance instructions supplied with this engine must be followed at all times. Flying any aircraft involves the risk of injury or death, building and maintaining your own aircraft require s great personal responsibility. Advisories This document utilizes three types of advisories; defined as follows: WARNING A warning emphasizes information which, if disregarded, could result in severe injury to personnel or equipment failure. CAUTION Emphasizes certain information or instructions, which if disregarded, may result in damage to the engine or accessories. NOTE Provides special interest information, which may facilitate performance of a proced ure or operation of equipment. Warnings and cautions precede the steps to which they apply; notes are placed in the manner which provides the greatest clarity. Warnings, cautions, and notes do not impose undue restrictions. Failure to heed advisories wi ll likely result in the undesirable or unsafe conditions the advisory was intended to prevent. Advisories are inserted to ensure maximum safety, efficiency, and performance. Abuse, misuse, or neglect of equipment can cause eventual engine malfunction or fa ilure.

10. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 10 ALL 19 - 3 - 2019 TOA (Table of Amandments) Current N° Chapter Page Change date Remark Date aproval Date inclusion Signature 0 0 INTRO Before operating the engine, carefully read this Operators Manual. The Manual provides you with basic information on the safe operation of the engine. If any passages of the Manual are not clearly understood or in case of any questions, please contact an D - Motor International® authorized aircraft engines dealer/distributors or their independent serv ice center. D - Motor International wishes you much pleasure and satisfaction flying your aircraft powered by this D - Motor® - A ircraft engine.

32. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 32 ALL 19 - 3 - 2019 Power Supply An engine with fuel injection requires for a safe operation a trouble - free power supply. The ECU receives all relevant data from the sensors, calculates the optimal ignition and injection time, as well as the required fuel quantity which needs to be inject ed and the injection duration. Therefore the ECU, but also the fuel pump, required a continuous and trouble - free power supply. The ECU controls and provides the ignition coils and the injectors with the required electric power. Any power supply interrupt ion of the ECU leads to an immediate stop of the motor. A safe function of the switches and a correct connection of the cables is therefore extremely important. Control and function test of the power supply While the engine is running, the integrated generator produces an alternative current which is converted by means of a digital transformer into direct current in order to charge the 12V battery. The generator is able to produce at low RPM enough current to provide the required electrical power for the fuel pump, injectors, ECU and the ignition without discharging the battery, even at idle regime. The charge condition is surveyed by the digital transformer and limited to 14V. All consumers are power supplied by the battery and all circuits are separately secured. The power supply on board is surveyed using the voltmeter and of the loading activities using the ammeter. The average current consumption on board, when the engine is running, including the radi o, transponder, glass cockpit and position lights amounts to approximately 10A if the battery is fully loaded. NOTE A decreasing voltage on board is an indication that the generator does not work properly or even has a total failure. If the generator has a failure all consumers are supplied only by the battery. If the on board voltage is lower than 8V the ECU stops working and the engine stops running. It is for that reason recommended to switch off all consumers and to land as soon as possible. The remai ning flight time depends on the loading condition of the battery and of its capacity. It is not allowed to operate the engine without battery connected to the generator. Aircrafts with more than one battery (Backup) at all - time one of the batteries must be connected via the transformer to the generator, while the engine is running.

20. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 20 ALL 19 - 3 - 2019 ASSEMBLY SHORT PROPELLOR FLANGE (Example) D - Motor offers different types of propellor flanges – check our price list or contact our sales team. HANDLING OF THE ENGINE Motor START The LF 26 does not have a choke or an intake air heating. Thanks to the ECU and the injection system the motor may be started at any temperature without any special precaution. The hand ling of the motor is based on following elements : • Key Switch Release to start • Start Button Activate the starter • ECU Fuse/Switch ON/OFF switch for the ECU with fuse function • Fuel pump Fuse/Switch ON/OFF switch for the fuel pump with fuse function • Ignition c ircuit (2x) ON/OFF switches of the ignition circuits • Throttle Regulate the power setting

6. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 6 ALL 19 - 3 - 2019 INTRODUCTION D - MOTOR Engines The D - Motor LF 26/LF39 is a 100% water cooled boxer motor with sidesteered valves for direct driven propellers. The motor has a lambda probe and performance map controlled multi field injection with double ignition. The 300W/25A generator is fully integrated; the oil and cooling liquid pumps are directly driven by the camshaft. The fuel pressure is hold at a constant level by a pressure regulator, which is connected to the back flow circuit. An intake air preheating is not required and not installed. The entire motor is controlled and surveyed by the ECU ( E lectronic C ontrol U nit ). A second ECU is standard, battery and fuel pump can be installed as a redundant system. During the use of the motor following data and information are constantly collected, analysed and interpreted by the ECU. The Engine is a Top quality European Produc t (produced and assembled in Belgium). https://www.d - motor.eu SCOPE AND PURPOSE OF THIS DOCUMENT This manual supplies instructions for engine preparation, installation, and operation of the LF26 and LF39 aircra ft engines. The installation instructions in this manual are basic guidelines. When installing the engine in the airframe, follow the airframe manufacturer’s installation instructions. Refer to the D - Motor Engine Service and installation manual for requir ed maintenance (service information) such as: oil changes, oil addition, oil filter replacement, routine time - interval inspections, routine service, spark plug replacement/inspection procedures, cylinder inspection, fuel system inspection, and scheduled se rvicing procedures. For airworthiness limitations, guidelines to isolate faults and for procedures to replace components, disassemble and assemble the engine, refer to the D - Motor Engine Maintenance Manual. For spare parts information, refer to the D - Motor last revision Illustrated Parts Catalog.

25. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 25 ALL 19 - 3 - 2019 Some sensors or systems are redundant, for example the ignition, the crankshaft sensors, etc. Other syst ems are optionally available in redundancy, fuel pump, battery, generator or additional injectors. Redundant systems serve to increase the reliability of the motor and not to allow flying if one system fails. In no case it is allowed to take - off if one sys tem failed on ground before take - off (for example one ignition circuit). Redundant systems allow continuing the flight until an airfield may be reached, a safe landing is secured and the failure may be fixed. • Unusual noises If any unusual noises occur, ma ybe combined with a high volume, than it is possibly that the exhaust system or the intake air system which is damaged. A defective exhaust system could mean that the exhaust gases are not totally transported outside the cowling and may even penetrate into the cabin. Or some hot gazes may heat other parts and create further damages. This means high danger for the pilot or the aircraft and a landing of the next airfield is to be initiated immediately. Once landed the problem may be found and fixed. Unusual n oise coming from the intake system points to problems coming from a defective or loose air filter system. This means danger for the motor, respectively the possibility of intake of additional air or worse, the suction of foreign particles into the engines combustion chamber, which may damage the engine seriously. This means to initiate the immediate landing on the next airfield as soon as possible and to fix the problem. • Heavy vibrations Since the LF 39 has an injection system carbur a tor icing cannot occur a nd not be the reason for heavy vibrations. This means that in case heavy vibrations occurs, they must come from other sources, like the propeller, loss of counterweights on the propeller, loose bolt holding the propeller, loose spinner, etc. Heavy vibrati ons can also be a sign of beginning engine failure or indicate the loss of one cylinder, for example due to an injection failure or a damaged ignition. In any case set a power setting with lowest vibration, but which still allows a safe flight and land on the next airfield. ECU ERROR MESSAGES Possible error messages coming from internal diagnosis of the ECU: Two leds are incorporated on the ECU housing, no LED lit = ALL OK ! All error diagnostic is logged. (See E.C.U. D - Motor Installation and troubleshooting manual) Indicated errors from the diagnose means that or the sensor is damaged, or that the parameter is outside the expected range. For example, if the temperature is t oo high.

2. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 2 ALL 19 - 3 - 2019 Supersedure Notice This manual is a revision of the instruction published in 2013 (and changes). Instructions in this document replace the instructions of previous D - Motor International Publications – Engine Owners Manual. Effective Changes for this manual / document February 2019 V1 March 2019 V2 Published and printed in B elgium by D - Motor International, bvba. Copyright ©2013,2015,2019 D - Motor International, bvba. All rights reserved. This material may not be reprinted, republished, broadcast, or otherwise altered without the publisher's written permission. This manual is provided without express, statutory, or implied warranties. The publisher will not be held liable for any damages caused by or alleged to be caused by use, misuse, abuse, or misinterpretation of the contents. Content is subject to change without notice. Other products and companies mentioned herein may be trademarks of the respective owners.

24. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 24 ALL 19 - 3 - 2019 Emergency Procedures Normally the engines for Ultra - light or LSA aircraft are not certified, but also a certification does not protect from engine failures. Please bear in mind that for any existing aircraft or any existing engine a failure is possible. If sight of a failure is recognized before the take - off the flight has to be cancelled in any case. In case of a failure in fligh t the right reaction is very important: • Failures indicated by the ECU Basically there are two kinds of failures, or indicated by a clear text message (if the monitor is installed) or by blinking, respectively constant glowing, of the LED. The first kinds of failures are those of the sensors or deviations of the measurements, but which is not an engine failure. For example, if the LED shows a constant glowing, the flight can continue until you reach the next airfield or an appropriated landing area. It does not mean an immediate danger. As for the second kind of failure, signalized by a fast blinking, this means that an emergency landing is to be initiated immediately. • Loss of cooling liquid Should your engine loose its cooling liquid during the flight (for example due a broken pipe) the temperature will rise instantly and rapidly. An emergency landing has to be prepared immediately. The remaining running time of the motor without cooling liqu id are a few minutes, this means that after the power setting has been reduced to idle, the remaining running time may be used just before landing. • Loss of power supply In case the on - board voltage gets too low, for example if the generator fails, the ba ttery is not loaded anymore. All consumers, also those required to run the engine are supplied by the battery only. Turn off all consumers which are not absolutely required and initiate immediately your landing on the nearest airfield. The remaining runnin g time depends on the size and on the loading status of the battery. If two batteries are installed having together 4.5Ah the remaining running time will be between about 20 and 30 minutes. • Sensor failure Some sensors are redundant; some values are in dire ct relation to other values. For example the cooling water is measured by two sensors, one to indicate the pilot the temperature, the second to supply the ECU. Now if the indicated temperature of the water is too high, but no warning coms from the ECU and the oil temperature shown is within the normal range, then for sure the sensor is damaged. Or if the oil temperature is extremely high but the water temperature and the oil pressure are normal then probably the sensor is damaged. If seems to be likely that a sensor failure occurred, it is not necessary to initiate an emergency landing. Land on the nearest airfield and repair the damage. • Redundant systems

40. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 40 ALL 19 - 3 - 2019 The engine does not develop full power Cause Action Ignition trouble Tighten all connections. Too much oil remaining in the crankcase Check oil return line. Fuel supply inadequate (less than 2,5 Bar) Check fuel filter. Incorrect fuel grade Refuel with prescribed grade fuel. Intake leaking Tighten all connections. Replace defective parts. Low oil pressure Cause Action Insufficient oil in oil tank Check oil level and fill if necessary Oil remains in engine and doesn’t circulate Check oil return line to tank High oil temperature See higher Pressure loss Check the pressure control valve. Air in suction line Vent the oil line. Defective oil pressure gauge Replace the oil pressure gauge. Bearings defective (no oil pressure) A major overhaul is necessary.

41. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 41 ALL 19 - 3 - 2019 The engine does not stop immediately Cause Action Idle speed to high Adjust proper idle speed (800 r/min) (1010 r/min for helicopters) Ignition switch defective Replace the switch. Excessive oil consumption Cause Action Piston rings or oil scraper rings worn A major overhaul is necessary Poor oil quality Change oil. Use prescribed oil. Worn valve guides or bad valve guide seals A top overhaul is necessary. External oil system leaky Check for defects and correct as necessary. Engine « knocks » Cause Action Using fuel with a low octane rating Use fuel with a higher octane rating. Engine hard to start at low temperatures Cause Action Low battery charge Replace battery or recharge. High oil pressure During a cold start a pressure reading up to 100 psi (7bar) is permissible

16. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 16 ALL 19 - 3 - 2019 Included accessories Delivered with standard engine package: • The engine with integrated alternator, water pump, oil pump and electric starter. • Rubber mounts (dimensions same as Jabiru and UL power) . • Fuel pump, fuel filter and injectors . • 2 ignition coils, spark plugs and ignition leads . • ECU and loom (standard redunda nt injection) . • 3 water temperature sensors (2 for ECU and one for instrument) . • Oil pressure and oil temperature sensor . • Oil filter, oil tank with breather system . • Exhaust pipes included and lambda probe , no mufflers are included. • The liquid cooling system (radiator, hoses and expansion tank) are not included. The different aircraft and helicopters, equipped, required different cooling configurations. It is too difficult to anticipate a solution for every installation. Attempting to provide a universal solution would be both inefficient and overly expensive. The weight of the engine completely installed with liquids is 85 and 88 kg depending on installation. This weight does not include the engine mount or propeller. The actual TBO time is 1500 hours. Options: • Plywood crate (FAO - IPPC - ISPM15), packaging and handling • Warranty: 2 year

22. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 22 ALL 19 - 3 - 2019 Motor STOP If possible the engine should not be stopped when it is very hot. As the cooling liquid and t he fuel are not pumped anymore it may create vapour lock problems due the residual heat. Generally it is enough if the landing is made with reduced power setting and following taxiing to cool down the motor temperature sufficiently to enable an immediate stopping of the motor. • Throttle set to idle • Switch OFF all electrical consumers. If a NESIS is installed it should be switched OFF only after the motor has been stopped, in order to secure the safeguarding of the log book and the last flight. • Switch OFF the fuel pump If the engine is still running for a few seconds, it reduces the rem aining pressure in the fuel system. • Switch OFF both ignition circuits, then the engine stops • Switch OFF the ECU • Turn OFF the start release key switch • For parking maintain this status and if required remove the key ENGINE Checking If the last flight has been without any conspicuous behaviour, then the pre - flight check is limited to following: • Control of cooling liquid Sight control of the overflow reservoir Open maintenance trap • Control of the oil level Sight control of the oil reservoir Open maintenanc e trap WARNING As usual with all engines having dry sump lubrication, the highest level is reached only after the propeller has been turned a few times by hand until the typical gurgling noise is heard from the oil reservoir. This reservoir installed in your aircraft is normally equipped with a sight tube showing the oil level and therefore the control of the level is made visually. MAKE SURE THAT ALL POWER SWITCHES ARE IN ‘OFF’ POSITION !!!

23. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 23 ALL 19 - 3 - 2019 It is recommended to notice the level before and after turning the propeller in order to memorise the increase of the level. Once this is memorised one may not need to turn the propeller each time to control the oil level as the increase should be always the same. Operation Same as for all engines, the way to treat your engine will increase or decrease tremendously the life - time, the consumption, the maintenance costs and deterioration of your engine. Following a few recommendations for the right use of the D - Motor type LF 39 : • The take - off or full power setting should be applied only once the engine, respectively the cooling liquid and oil has reached its minimum temperature of 50°C. • It is recommended to reduce the power setting after the take - off and once you reached the safety altitude, and to fly inste ad a little bit faster. Even if the aircraft does not climb as fast as possible, in total you reach faster your destination, and the most important it means less consumption and deterioration. It is recommended not to hang the aircraft at the propeller, if it is not required to climb as fast as possible due to geographical obstacles. • To fly fast does not always mean to gain a lot of time to reach your destination. By reducing the power setting speed is reduced only slightly, but the consumption is massivel y lower. Further your range is much higher. Please see therefore the consumption table under paragraph “7.5 Range and Fuel Consumption”. • Avoid rapid changes of the power setting (except in case of emergency). It is better to increase or decrease the powe r setting slowly but constantly. Massive power setting changes in a short time does always means high stresses for the crankshaft, especially for direct driven engines. • Each engine coming from serial production has its typical behaviour at different regime s. This is like a character of each individual engine. Even if the LF 39 is an engine which runs extremely smoothly, it’s recommended to avoid regimes where your engine shows up with more vibrations. Often the RPMs of higher of fewer vibrations are nearby a nd only a few RPMs away from each other. • In case your engine shows unexpectedly starting difficulties they may occur from impurities in the injectors or on the spark plugs. These impurities may be eliminated by using a special cleaning program. To start th e cleaning program, set the throttle to full power setting, switch on the ignition and the ECU, and activate the starter for a few seconds. In this configuration the engine will not start, but initiate only the cleaning program. After running the cleaning program switch OFF the ECU, then switch the ECU ON again and try once more to start up the engine in the normal way.

39. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 39 ALL 19 - 3 - 2019 Warm engine shows irregular idling Cause Action Intake manifold leaky Tighten all intake connections. Replace any defective parts. Engine runs erratic or misfires occasionally Cause Action Spark plug failure Clean plugs inside and outside. Replace if necessary. Ignition wire breaks down Check ignition wire and replace if necessary. Ignition troubles Check complete ignition system and replace parts if necessary. Fuel filter blocked (fuel pressure indicator below 2,5 Bar) Disassemble and replace the filter. Engine overheats, Oil temperature over 100 D eg.C (212 deg.F) Cause Action Too much oil remaining in the crankcase Check the oil return line Insufficient air - flow to the oil cooler Check and clear the air passages. Insufficient oil supply Check oil level and fill if necessary. Poor oil quality Change oil. Use prescribed oil. Oil filter blocked Change the oil filter. Defective oil temperature gauge Replace the oil temperature gauge. Excessive piston ring gas leakage (blow by) Major overhaul is necessary. Bearings defective If there is metal contamination in the crankcase sump, a major overhaul is necessary.

37. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 37 ALL 19 - 3 - 2019 200 - hour - inspection • carry out the 100 - hour - inspection. • Check the spark plug caps. Change if necessary. • Change the fuel filter. • Chang e the air filter. Preservation of the engine for long term storage For long out of operation periods and at extreme climatic conditions, we recommend the following instructions to protect against corrosion. Extra protection against corrosion beyond these recommendations is not necessary. 1. Change the engine oil in accordance with the section in this manual 2. Blank all openings, the exhaust tubes, the breather tube and air filters. Place in a large heavy duty plastic bag with a minimum of 4KG of desiccant bags. Take care not to puncture the plastic storage bag. Using a vacuum cleaner, draw all the air out of the storage bag and seal the neck of the bag by gathering the neck, folding it back on itself and clamping with a large ty - wrap. Re - activat e the desiccant bags at least once a year by placing in a warm oven at 100 deg c for several hours. Bringing the engine back operation remove all the protections !!! Winter operation Care of the electrical system Generally in the beginning of the winter an engine inspection shall be performed. • check all the connections of the ignition system and clean if necessary. CAUTION! F or longer storage periods, the preservation procedures must be performed at least annually.

21. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 21 ALL 19 - 3 - 2019 After the pre - flight check and provided the propeller area is free the motor is started : • Release the start with the key switch • Fuel pump - ON • Both ignition circuits - ON • ECU – ON (if the outside air temperature is low the ECU may be switched 2 or 3 times ON and OFF in order to simplify the starting procedure. • Throttle set on idle position, res pectively control the idle position • Push the starter button until the motor starts. Try for maximum 10 seconds, and then stop the starting process. Wait a few seconds and try again to start the motor. • As soon as the motor runs increase the RPM after a few seconds • Switch on the monitoring instruments and check the oil pressure • Warm up with about 1200 RPM If the oil pressure is insufficient or in case of an error message from the ECU, stop the engine and if necessary investigate for the problem. If no error is reported and the oil pressure is sufficient warm - up the motor until the oil and water reach about 50°C. Check both ignition circuits before take - off. To do so increase the power setting up to 2000 RPM and switch OFF circuit 1 for about 5 se conds, monitor the RPM which shouldn’t change for more than 50 RPM. Proceed in the same way with circuit 2. The difference between the decreases while checking both circuits shouldn’t exceed 30 RPM. While checking both circuits, as soon as one circuit is switched OFF the ECU should report this error by means of the blinking LED or by the corresponding text message on the engine monitory instrument. CAUTION! Never start the engine without prop installed. Otherwise the engine will be damaged.

38. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 38 ALL 19 - 3 - 2019 • Check the battery voltage. • The battery poles and terminal connectors should be cleaned. • Check the liquid coolant mix is suitable to cope with an outside air temperature of - 36 deg C. In Countries w ith extremely low temperatures it is recommended to protect the battery against freezing by keeping it in a warm location for storage between flights. Cold starting procedures Throttle OFF Limit cranking the engine for periods longer than 10 sec. After the engine starts, keep the engine running but do not exceed 2000 RPM until the oil temperature reaches 50 deg C (122 deg F). TROUBLE SHOOTING Engine does not fire Cause Action Ignitions OFF ON. Spark plug gap too big Change plugs or re - gap plugs. Fuel shutoff valve OFF or fuel filter blocked Fuel shutoff valve ON, clean or replace fuel filter. Lack of fuel Fill fuel tank. Ignition line loose or damaged Check line connections. Replace if necessary. Battery defective or discharged Install charged battery or recharge. Starting speed too low, start problems Check battery. Spark plugs wet from condensation Dry plugs inside and outside. Spark plugs wet with fuel (over - choked) Dry spark plugs. Inner mechanical defect Contact engine manufacturer or approved service centre.

14. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 14 ALL 19 - 3 - 2019 Description The D - Motor LF 39 is a 100% water cooled boxer motor with side steered valves for direct driven propellers. The motor has a lambda probe and performance map controlled multi field injection with double ignition. The 300W/25A generator is fully integrated; the oil and cooli ng liquid pumps are directly driven by the camshaft. The fuel pressure is hold at a constant level by a pressure regulator, which is connected to the back flow circuit. An intake air preheating is not required and not installed. The entire motor is contro lled and surveyed by the ECU ( E lectronic C ontrol U nit). Standard is a redundant second ECU, battery and fuel pump and is installed as a redundant system. During the use of the motor following data and information are constantly collected, analysed and i nterpreted by the ECU • Throttle valve position • Intake air temperature • Crankshaft position analogue • Crankshaft position digital • Air pressure • Cooling liquid temperature • On - board power supply voltage • R PM • Lambda probe values If one of the sensors fails, the ECU change into a standard or emergency program, in which the motor continues to run, but eventually with less power and increased consumption. The ECU signalizes its status by means of LEDs on the ECU Casing, or optionally by means of a separate monitor. As the option of a redundant system is installed by default(by the ECU, Battery and Fuel pump, etc.) the redundant systems controls themselves reciprocally. The full operation is still assured if one circuit fails totally . Due to the sidesteered design of the motor, some motor failures (for example valve tearing) wouldn’t stop the motor to work. Inflight even a loss of one or two cylinders can be compensated and the motor continues to run with less power, which enables t o initialize a safety landing. The power supply is very important for a safe operation of the motor. Should the generator fail and the battery is not charged sufficiently anymore, the motor continues to run only until the minimum power supply voltage of 8 V is reached.

12. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 12 ALL 19 - 3 - 2019 Oil pressure 1.5 - 5.0 bar Oil specificati on Synthetic 5W50 - 5W40 - 0W50 – 0W40 Oil quantity 3 .5 Lit ers Oil filter Mahle OC 475 (11 W 27) Oil temperature min 50° C to 120° C 80°C to 100°C best range Cooling liquid Water with antifreeze and anticorrosive (for Aluminium motors) Cooling liquid te mperature 50°C to 110°C (opening pressure at 1.2 bar) – peak value 50°C to 120°C (opening pressure at 1.4 bar) – peak value 75°C to 95°C best range – Endurance max 100 °C Cooling liquid pump pump driven by camshaft Propeller flange bolt - hole circle dia. 101.6 mm 6 x 13mm Spa rk plug Beru "Ultra X Titan UXT 1" / Beru Ultera R1 - 537 Ignition coil Bosch RB 110322 - 2 Plug Bosch 90° angled, rubberized Lambda probe Bosch

30. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 30 ALL 19 - 3 - 2019 If a fuel pressure indicator is installed, it may be used to recognize irregularities of the fuel system or of the fuel pressure. NOTE Strong indicators of upcoming problems or failures within the fuel supply system are unsteady or constantly low fuel pressure. Blocked filters, bended pipes or a damaged fuel pump could be the source of these problems. Too high fuel pressure is an indication of a damaged regulating valve or a blocked back flow pipe. Once these signs recognized it is mandatory not to take off again and if in flight to land as soon as possible on the nearest airfield. Defective s witches or fuses within the fuel supply system have to be replaced before next flight. Important Information fuels and lubricants : Fuel : Automobile fuel, unleaded premium 95 Octane (RON) minimum. Fuel pressure : 2,5 BAR Oil type : Fully synthetic branded automotive oil to API SJ standard as a minimum. Engine warranty is void if oil is used that is below this standard. Oil volume: 3 ,5 Litres Oil level is between Ensure between max. & min. On standard oil tank 2 cm above middle of the tan k. Oil pressure: 1,5 Bar @ 2000 RPM 0,8 Bar @ idle RPM Oil temperature (readings off of the feed line into engine): Min. 50 Deg.C (122 Deg.F) Max. 110 Deg.C (230 Deg. F) Optimum oil temperature range : 80 – 100 Deg.C (170 - 212 F.) CAUTION! Don’t use any additives

15. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 15 ALL 19 - 3 - 2019 The above is one option, please contact our sales team for all possible options , incl. heli options. Short specification list • Type : D - motor LF39 • Class : Microlight aircrafts • Engine : 6 cylinders, four stroke, liquid cooled • Displacement : 3993 cc • Stroke : 79 mm • Compression ratio : 8/1 • Max power : 125 Hp at 3000 RPM • Max continuous power : 112Hp hp at 2800 RPM • Used fuel : 91, 93, 95 oct. 98 oct. or avgas • Fuel consumption : 19 liter at 75% performance • Maximum torque : 285 Nm at 2500 RPM • Intake : Multipoint sequential fuel injection • Alternator : 25 Amp integrated • Electric starter : 1.1 KW integrated • Ignition : Double • Installed dry weight (liquids 7kg) : 78 kg

36. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 36 ALL 19 - 3 - 2019 Periodic inspections After the first 25 hours of operation the inspections listed in 6.2.1 are to be performed. The next inspection is due to at 50 hours and thereafter every 100 hours. The 100 - hour inspection mentioned is to be performed every 100 hours but at least annually. The 200 - hour inspection is to be performed every 200 hours. First 25 & 50 - hour - inspection • Check condition of the throttle cables, choke cables. • Engine mounts. Check for cracks, looseness of mounts, and looseness of engine to mounts. • Check for looseness of bolts, nuts and pins. • Check for oil leaks from hoses, the oil tank and fittings. • Perform an oil change and send sample to constructor • Change the oil filter. • Fuel lines - check the standoffs, safeties, leaks and wear. • Fuel filter - check, clean. • Check the ignition harness for damage and tight connections at spark plug cap. • Air filter - check, clean. • Check the fuel lines. • Check the general condition of the exhaust system; look for cracks, particularly at the welds. • Check the muffler and attaching flanges at the exhaust ports on the cylinders for exhaust leaks. • Check the ignition co ils for wear and security of attachment. • Check for leaks at the oil pressure and temperature sensors. • Electrical wiring - check for wear, damage and security of attachment. • Check the crankcase for leaks and cracks. • Clean engine if dirty or oiled. • Run up the engine . 100 - hour - inspection or annually • carry out the 50 - hour - check. • Perform a compression check. • Change spark plugs.

11. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 11 ALL 19 - 3 - 2019 MAIN SECTION Technical Sheet LF 39 type D - Motor Engine Producer D - Motor, Belgium Construction 6 cylinder boxe r motor, four stroke Reduction gear Non Cooling fully liquid cooled Control unit ECU – 12 V 8A for ECU and fuel pump required Intake Multipoint sequential fuel injection Ignition Double CDI, controlled by ECU Generator 300 W/25A integrated Bore 103. 5 mm S troke 80 mm Displacement 3.900 cc Compression 8 .1/1 Starter 12V - 1.1 KW integrated Fuel pressure 2.5 – 3.0 bar Fuel regulator 2.5 bar opening pressure, in the back flow Fuel MOGAS Super leadless 95 ROZ, or AVGAS Fuel filter Bosch N. 6462 Ultra - fine filter, pressure side operated Power 125 HP at 3. 1 00 R PM Torque 2 83 N m at 2. 5 00 R PM Rage of use 800 to 3 1 00 R PM 2100 u/min to 2800 u/min in Cruise Lubrication Dry sump Oil pump Pump driven by camshaft

33. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 33 ALL 19 - 3 - 2019 Spark plugs • Spark plugs should only be removed when engine is cold. • Brush clean with a plastic bristle brush. • Do not use a brass brush or a steel wire brush for cleaning. • After 200 hours or at least annually. Replace spark plugs. • Spark plug type: Beru UXT 1 / Beru Ultra R1 - 537 • The engine must be cold before the spark plugs are torque tightened. . TABLE FOR TORQUE VALUES Nm Oil drain screw M22 1 5 Oil pump screw (banjo) M18 32 Crankcase screw small M6 12 Crankcase medium * M8 34 Crankcase screw big M12 110 Crankcase screw front M8 34 Rods M8 42 Cylinder head M6 12 Mounting plate M6 14 Oil pump M6 12 Fl ange M20 240 Screw for starter M5 7 Intake manifold screw M5 7 Water pump housing M5 7 Gear on camshaft M6 18 Extension crankshaft M6 18 Screw - nut alternator M20 60 Bolts cylinders to crankcase M8 34 Spark plugs M14x1.25 22

4. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 4 ALL 19 - 3 - 2019 Spark plugs ................................ ................................ ................................ ................................ ........ 33 TABLE FOR TORQUE VALUES ................................ ................................ ................................ ................. 33 Performance Curve of the LF39 Engine ................................ ................................ ................................ . 35 Periodic inspections ................................ ................................ ................................ .............................. 36 First 25 & 50 - hour - inspection ................................ ................................ ................................ ........... 36 100 - hour - inspection or annually ................................ ................................ ................................ ....... 36 200 - hour - inspection ................................ ................................ ................................ .......................... 37 Preservation of the engine for long term storage ................................ ................................ ................. 37 Winter operation ................................ ................................ ................................ ............................... 37 Care of the electrical system ................................ ................................ ................................ ......... 37 Cold starting procedures ................................ ................................ ................................ ............... 38 TROUBLE SHOOTING ................................ ................................ ................................ ............................. 38 Engine does not fire ................................ ................................ ................................ .......................... 38 Warm engine shows irregular idling ................................ ................................ ................................ . 39 Engine runs erratic or misfires occasionally ................................ ................................ ...................... 39 Engine overheats, Oil temperature over 100 Deg.C (212 deg.F) ................................ ...................... 39 The engine does not develop full power ................................ ................................ ........................... 40 Low oil pressure ................................ ................................ ................................ ................................ 40 The engine does not stop immediately ................................ ................................ ............................. 41 Excessive oil consumption ................................ ................................ ................................ ................. 41 Engine « knocks » ................................ ................................ ................................ .............................. 41 Engine hard to start at low temperatures ................................ ................................ ......................... 41 OVERHAULS ................................ ................................ ................................ ................................ ........... 42 Major inspections at TBO ................................ ................................ ................................ .................. 42 Major repairs and major modifications ................................ ................................ ............................. 42 Page intentionally left blank ................................ ................................ ................................ ................... 43

3. The Light Weight Engine Houtekietstraat 11 B - 8540 Deerlijk, Belgium EFFECTIVITY page 3 ALL 19 - 3 - 2019 Inhoudsopgave Blank Page (intentionally) ................................ ................................ ................................ ......................... 5 INTRODUCTION ................................ ................................ ................................ ................................ ....... 6 D - MOTOR Engines ................................ ................................ ................................ .............................. 6 SCOPE AND PURPOSE OF THIS DOCUMENT ................................ ................................ ........................ 6 Warning ................................ ................................ ................................ ................................ ............... 7 Advisories ................................ ................................ ................................ ................................ ............ 7 Order of Precedence ................................ ................................ ................................ ........................... 8 Updates/Changes Distribution ................................ ................................ ................................ ............ 8 Suggestions and corrections ................................ ................................ ................................ ............... 8 Contact Information ................................ ................................ ................................ ............................ 9 TOA (Table of Amandments) ................................ ................................ ................................ ............. 10 MAIN SECTION ................................ ................................ ................................ ................................ ....... 11 Technical Sheet LF39 type D - Motor Engine ................................ ................................ ...................... 11 Description ................................ ................................ ................................ ................................ ........ 14 Center Of Mass (CG) ................................ ................................ ................................ .......................... 19 ................................ ................................ ................................ ................................ ........................... 19 HANDLING OF THE ENGINE ................................ ................................ ................................ ................... 20 Moto r START ................................ ................................ ................................ ................................ ..... 20 The handling of the motor is based on following elements ................................ .......................... 20 After the pre - flight check and provided the propeller area is free the motor is started .............. 21 Motor STOP ................................ ................................ ................................ ................................ ....... 22 ENGINE Checking ................................ ................................ ................................ ............................... 22 Emergency Procedures ................................ ................................ ................................ ...................... 24 ECU ERROR MESSAGES ................................ ................................ ................................ ...................... 25 Safety / Avoiding failures ................................ ................................ ................................ .................. 26 Loss of Cooling liquid ................................ ................................ ................................ ........................ 26 Oil Supply ................................ ................................ ................................ ................................ ........... 27 Throttle adjustments. ................................ ................................ ................................ ........................ 28 Fuel Supply ................................ ................................ ................................ ................................ ........ 29 Important Information abou t fuels and lubricants : ................................ ................................ ........ 30 Power Supply ................................ ................................ ................................ ................................ ..... 32 Control and function test of the power supply ................................ ................................ ............. 32

Views

- 3508 Total Views

- 3032 Website Views

- 476 Embeded Views

Actions

- 0 Social Shares

- 0 Likes

- 0 Dislikes

- 0 Comments

Share count

- 0 Facebook

- 0 Twitter

- 0 LinkedIn

- 0 Google+

Embeds 2

- 9 d-motor.eu

- 6 ww2.d-motor.eu

-

EngineOperationsManual_LF26_2019_2

3227 Views .

-

Stampe SV4-RS D-Motor Maiden Flight

4880 Views . -

edm aerotec - CoAX 2D - AERO 2017

4345 Views . -

COAX 2 D Heli -Take off

4225 Views . -

-

D-motor LF39

3543 Views . -

EngineOperationsManual_LF26_2019_2

3227 Views . -

EDM KOAX Hubschrauber 29 Oktober 2016

3226 Views . -

Service Bulletin D- Motor 2019-012

3138 Views . -

Propellor Flange Standard

3084 Views . -

D Motor start South Africa

3073 Views . -

Zenair CH650Ei, with D motor LF26

3037 Views . -

EDM 2DCoax ULMH

3026 Views . -

D-motor Hawk 03/2012

2812 Views . -

Engine_Logbook_2019_LF39_rev1

2782 Views . -

The new microlight engine, visit www.d-motor.eu

2782 Views . -

Edm aerotec Flugsimulator powered by D-Motor

2716 Views . -

Engine_Logbook_2019_LF26_rev1

2579 Views . -

-

D motor LF26 on C42

2440 Views . -

3 New Aircraft Engines - Airventure Oshkosh 2018

2433 Views .